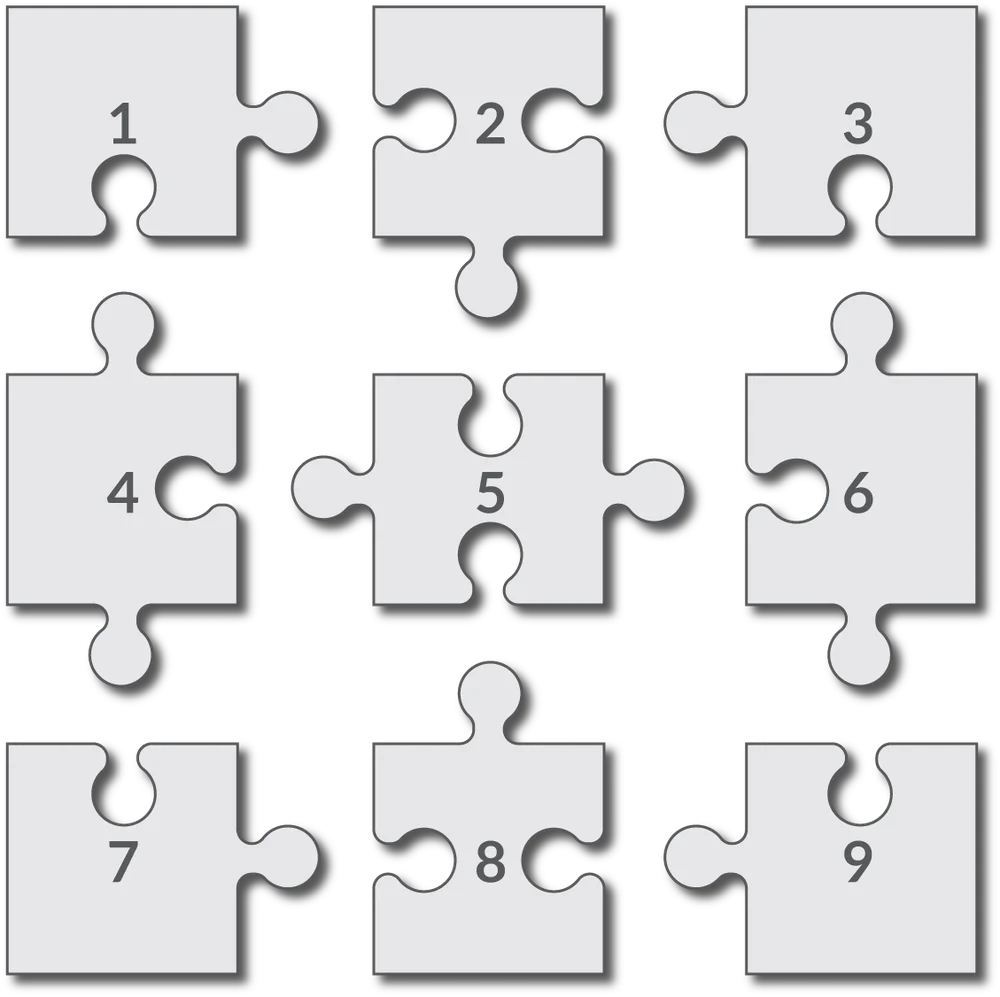

The 9 phases of a simulation project

Before launching a simulation pipeline to optimize the enterprise’s business processes, you should determine if simulation modeling is even the right tool for the job. If common sense or critical analysis can easily be applied to the problem, the use of simulation may be overkill. Moreover, sometimes employing algorithms and mathematical computations (Banks & Gibson, 1997) may increase the speed of execution, while reducing the cost of the simulation.

If it’s indeed superior to alternatives, initiate the simulation journey by outlining its steps!

Simulation modeling is a multi-stage endeavor that requires a structured approach. A detailed action plan is necessary to keep the project under control. If the project’s scope is not clearly understood, a lot of time will likely be wasted trying to adjust things on the go.

In the hope of supporting the team to gain a more precise understanding of how the simulation project should be laid out, the key phases of simulation modeling are introduced below!

The 9 steps of simulation modeling

1. Identify the problem

The very first step in a simulation modeling project is identifying what issues need to be solved. Without a problem definition, a sound and effective plan for simulation will not be developed.

Here, the main question to answer is – “what are the problems that need to be solved?”

The precise goals of the simulation efforts will depend on the state of the enterprise’s system. For example, if the current system’s appetite for resources is unacceptable, one goal could be to reduce costs. Or, if you want to scale operations up, the goal could include efficiently increasing system capacity.

2. Formulate the problem

The problem formulation phase is the foundation for a detailed, concrete plan of action for subsequent steps. While the previous phase was concerned with the “what” aspect of the problems, this phase defines the “how” to proceed (Chung, 2003).

More specifically, formulating the problem means quantifying the efforts and making progress measurable. With that in mind, the actions that can be taken at this stage include:

- Define specific objectives of the study.

- Identify the end-user/primary stakeholder of the simulation.

- Identify if a simulation is the right solution/approach.

- Identify alternative systems and methods to be evaluated.

- Break the project down into milestones.

- Define and select quantitative metrics for comparing proposed solutions.

- Determine the areas of the system that need to be studied.

- Define a timeframe for the simulation project.

Don’t forget to coordinate the efforts with the stakeholders to ensure that the flow of the project makes sense and that its goals and objectives match their expectations.

3. Outline a model

Once a concrete plan exists, construct the conceptual and logical models that will be used to achieve the goals. To do this, a meticulous understanding is needed of the target system and how its components interact with each other.

Flow charts and diagrams are the greatest allies at this stage since they can help promote a visual grasp of how the model should operate. Your conceptual model doesn’t need to capture the real system in all detail – only a model that can represent features relevant to the enterprise’s goals is needed. The complexity may be increased later if required.

A critical success factor would be to involve the end-users of the model in the conceptualization stage – this would allow the team to actually meet the user’s needs. By involving end-users, you would consequently increase their confidence in the efforts.

4. Model the inputs for the simulation model

Input modeling is arguably the most important step in simulation – take care to get it right! Input modeling is a complicated process encompassing four phases:

- Data collection.

- Identification of a probability distribution for input modeling.

- Selection of parameters for the probability distribution.

- Estimation of the goodness of fit of the probability distribution.

The ability of the model to solve real-world tasks directly depends on the quality of the input data. As they say, you get garbage outputs if you give your model garbage inputs.

Data that is poorly processed, badly understood, or isn’t representative of the system under consideration will not support the enterprise to achieve its goals. If quality data is acquired and correctly interpreted, chances of success will be dramatically increased!

5. Translate the model into code or software

The fifth step in your simulation efforts would be focused on transferring a model from the drawing board into the real world. Two options arise with model translation:

- Use a simulation software package (like Software Delivery Simulator).

- Implement the model from scratch.

Simulation software will likely be just right for most use cases. By facilitating planning, input modeling, and verification & validation, simulation software allows the team to avoid manual steps and focus on what matters most to the project’s success.

On the other hand, if some hyper-specific issues exist, off-the-shelf packages may not meet the team’s needs. In that case, the model could be built from scratch using programming languages like Rust, R, or Python. Rust is an excellent option, thanks to its emphasis on performance and memory safety.

6. Verify and validate the model

Verification and validation help to ensure that a sound model was created. More specifically:

- Verification makes sure that the model operates as intended, in accordance with the assumptions and the model’s technical specifications.

- Validation makes sure that the model can represent its target system with adequate accuracy.

If a model doesn’t pass both verification and validation, it’s not ready for deployment. A model that fails verification shouldn’t even be considered for validation. Even if your model does pass verification, the model shouldn’t be allowed into the subsequent phases of the project until it also passes validation against the real system.

7. Experiment with alternative models

At the experimentation step, alternative solutions should be developed and tested. Although your “main” model may seem good enough for the job, several simulation runs should be performed with alternative architectures and concepts. This will permit the team to ascertain that the model is indeed the optimal solution in your situation.

Make sure to check alternative solutions against the quantitative metrics defined in step 2 – this will support the team’s decisions with hard facts.

8. Document and report the simulation’s performance

Documentation is the step where all results and findings are reported to stakeholders for final decision-making. The project’s ultimate fate will depend on how convincing the findings are, so make sure to present the proposed solution appropriately!

The final report should outline the following:

- The current state of the target system and the improvements the simulation is expected to convey to the enterprise.

- The probable alternatives and how they compare with the suggested model.

- Metrics used to compare models and present improvements to the target system.

- Recommendations of the optimal solution to the problem in question.

Don’t leave documentation and reporting until last. If possible, develop documentation throughout the project – that way, the team won’t have to go back to the previous steps to collect the necessary data for the report.

9. Implement and update the model

Once you hopefully get the green light from the stakeholders, bringing the team’s ideas into the real world is critical! If all the steps are correctly executed right up until this point, impassable challenges should not be encountered.

Consequently, an important outcome realized here is that the project doesn’t end with implementation. The team will likely need to make changes to the simulation as the target process evolves and changes. So, although most of the work will be completed, once implementation is reached, additional actions will need to be executed beyond production deployment!

Next steps

As a final piece of advice, remember that there is no one-size-fits-all simulation plan for every problem. The team’s situation may seem unique, and thus, an equally unique approach to make may be necessary to achieve success.

The steps outlined above aren’t set in stone – they may be reshaped and adjusted in any way to adapt to the project! Slightly different formulations of the simulation process may be discovered online – choose one that appears to be the best match to the problem at hand.

References:

Banks, J., & Gibson, R. (1997). Don’t simulate when… 10 Rules for determining when simulation is not appropriate. Institute for Industrial Engineering Solutions, 29, 30-33.

Chung, C. A. (Ed.). (2003). Simulation modeling handbook: A practical approach. CRC press.

Greenwood, A. G. (2020, December). A specification for effective simulation project management. In 2020 Winter Simulation Conference (WSC) (pp. 2482-2492). IEEE.

Pereira, T. F., S. Robinson, J. Montevechi, M. de Oliveira, A. Banerjee. 2018. “Methodology for the Management of Discrete-Event Simulation Projects based on PMBoK: Action Research in a High-Tech Company”. In Proceedings of the 2018 Winter Simulation Conference. edited by M. Rabe, A.A. Juan, N. Mustafee, A. Skoogh, S. Jain, and B. Johansson. pp. 4002-4013. Piscataway, New Jersey: Institute of Electrical and Electronics Engineers, Inc.

Yin, C., & McKay, A. (2018). Introduction to Modeling and Simulation Techniques. In Proceedings of ISCIIA 2018 and ITCA 2018. Leeds.