Operational excellence – the key to low-cost product leadership

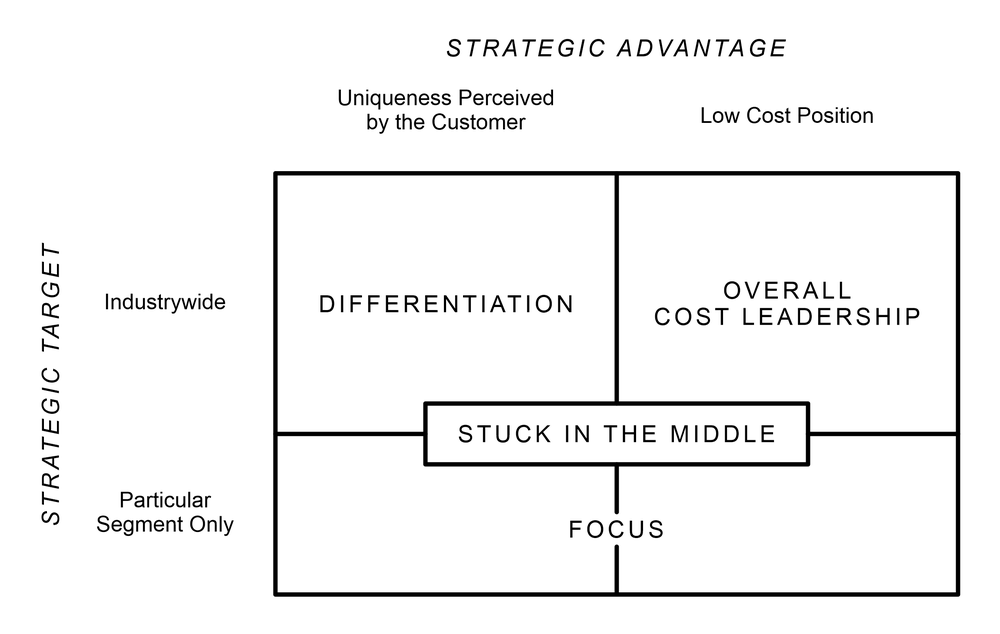

In 1980, Michael Porter (arguably the most cited author in business and economics) laid out three “generic strategies” that companies could follow to achieve success by demonstrating competitive advantage and effectively scoping the market. This was groundbreaking work because current thinking at that time acknowledged only one strategy: “to be profitable you must fight for market share and beat the competition.”

Empirical evidence suggested otherwise to Porter. He confirmed that many profitable companies did, indeed, command large market shares. But he also discovered smaller companies that used segmentation to mine small market niches profitably. In the middle ground between the two profitable groups, he found less successful companies.

He developed the following three generic strategies:

- Cost leadership: The enterprise can target customers in nearly every segment of an industry if the firm can offer the lowest price. The firm needs to be able to operate at a lower cost than its competitors by achieving:

- high asset utilization;

- low direct and indirect operating expenses; and

- control over the value chain encompassing all functional groups to ensure low costs.

- Differentiation: The enterprise can target customers in nearly every segment of an industry if the firm competes based on differentiation – best quality, stellar service, etc. Variations of the differentiation strategy include:

- shareholder value model, where the well-timed use of specialized, unique knowledge unlocks stakeholder value and creates a differentiation advantage.

- unlimited resources model, where enterprises more easily manage risk and sustain profits, compared to competitors, by leveraging resources asymmetry.

- Focus: The enterprise can target a few (or only one) segments. Within that segment, though, the firm needs to apply cost leadership or differentiation to its advantage. The focus strategy entails two alternates: lower costs and differentia

- lower costs.

- differentiate within the focus

Porter made a significant contribution by offering choice as a feature of marketing strategy. Companies were no longer tied to a bigger-is-better approach. Porter’s theories, and variations on them, dominated marketing strategy for decades.

The weakness of generic strategy

The biggest weakness of Porter’s model was: “How often are the model’s rules broken by exceptions?” Porter described the result of not following his unary approach to strategy: “The firm will be stuck in the mud.” He suggested that cost leadership and differentiation strategy were mutually exclusive, and trying to accomplish more than one strategy would result in loss of focus. Porter eventually came to accept that a hybrid business strategy could exist.

Researchers found many tremendously successful companies that didn’t follow Porter’s rigid guidelines. Hybrid strategies (low cost and differentiation) were achieving sustainable competitive advantage. Hybrid strategies are more difficult to operationalize than generic, single-focus strategies. But companies that can operationalize them outperform competitors. IKEA, Dell, Toyota, and Sony are examples of such success.

Follow the leaders

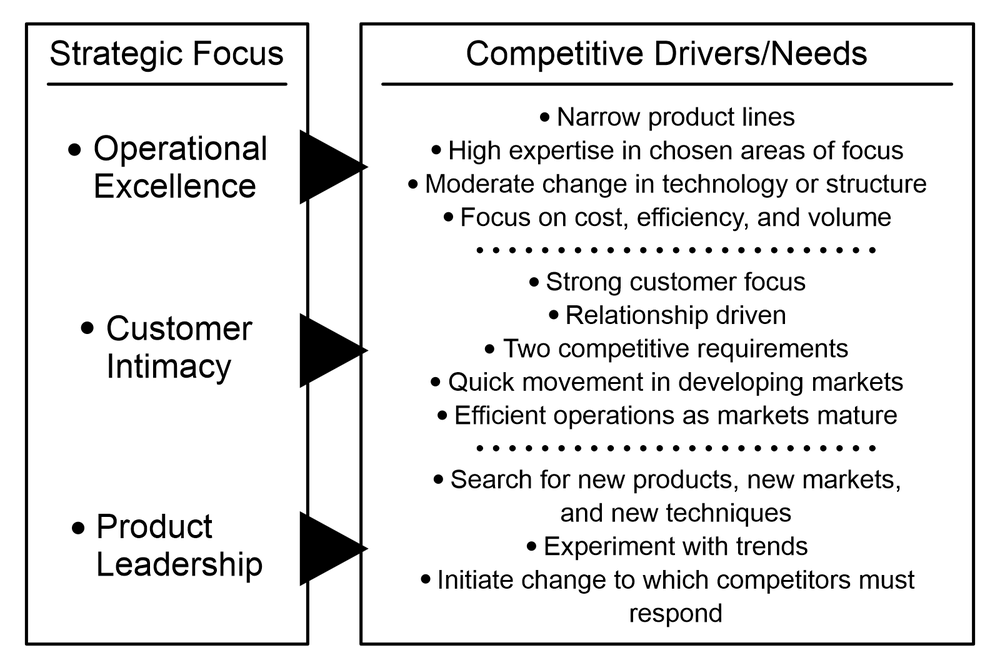

Accordingly, the authors of The Discipline of Market Leaders, Michael Treacy and Fred Wiersema, reworked Porter’s generic strategies based on their research of successful companies: Dell, Walmart, Southwest Airlines, Intel, Home Depot, and others. They created a model based on three dimensions, or Value Disciplines, that could be complementary, rather than mutually exclusive. Through the savvy application of the model, a business can create a differentiated product that’s also strong in cost leadership.

Overall, successful companies maintain successful performance in each of the value disciplines, with a primary focus on one:

- Customer intimacy – Design products and services to satisfy the customer persona(s) of the firm, building long-term customer loyalty.

- Product leadership – Seek to produce state-of-the-art products and services, over and over again.

- Operational excellence – Organize production and delivery of the products or services, leading the industry in price and convenience.

Operational excellence

“To leverage operations to attain business growth, the primary step is to know what Operational Excellence is, and so how we achieve it. Think of it as answering the question: Where will this journey of improvement take us? A good answer is that this journey will take us to the purpose at which every employee can see the flow useful to the customer, or operational excellence, and fix that flow before it breaks down.”

—Kevin Duggan, Founder of the Institute for Operational Excellence

Operational excellence is the key to keeping the disciplines complementary, rather than contradictory. Operational excellence means getting the best out of the firm’s people, processes, and assets. Public recognition of operational excellence has increased over the last 40 years recognizing individuals or organizations. Such awards include:

- Deming Prize,

- Malcolm Baldrige National Award,

- European Quality Awards, and

- AKAO Prize.

Many models of operational excellence exist.

Figure 3 was architected by Frank Adler, one of the thought leaders in the field of Operational Excellence, and consists of four dimensions:

- Strategy Deployment— the process of aligning and linking strategy or policy with execution;

- Process Excellence— the process of delivering world-class results through efficient and effective management process, value chain process, and support processes;

- Performance Management— the process of translating strategic initiatives into measurable objectives and goals (key performance indicators); and

- High-Performance Work Teams— the process of achieving and sustaining human talent who encompass the best attitude, a first-class mindset, and optimal competencies.

Operational excellence can build on continuous improvement tools such as Lean Thinking, Kaizen, and Six Sigma. But it tweaks continuous improvement by changing an organization’s focus from how to improve (operations) to why improvement is important (business goal). McKinsey & Company carried out research that noted that more than 70% of organizational transformations fail, such as those attempting to move toward operational excellence. The common causes for failure are flawed leadership and poor communication.

See how it works

“We do not act rightly because we have virtue or excellence, but we rather have those because we have acted rightly.”

—Aristotle

In our high-velocity business environment, the firm’s ability to meet changing customer demands is a critical success factor. The firm’s response time encompasses every system the organization runs, from beginning to end. That’s why Mean Time to Respond to Changing Customer Demand (MTTRCCD) has become a common measure of operational excellence. Let’s explore the symbiosis between operational excellence, MTTRCCD, and a hybrid marketing strategy.

Flexible innovation

The basic definition of the Lean Business Model – seeking to eliminate waste while satisfying customer wants – suggests the importance of innovation. Lean Innovation has emerged as a discipline in its own right. Lean Innovation focuses on capturing customer feedback early and often. Intimacy with what customers desire lessens the odds of waste from investing in unwanted products or features. When continuous customer feedback meets the Lean Culture of every employee as a master problem-solver, the firm creates a rich environment, where continuous, incremental improvements and disruptive, innovative ideas emerge.

Improved timeline

The Lean Business Model provides a range of tools to improve a firm’s timeline by eliminating waste. Tools include bottleneck analysis, Just-in-Time (JIT) production, value stream mapping, overall equipment effectiveness (OEE), plan do check act (PDCA), error-proofing, and root cause analysis (RCA). For example, Mixed Model Line Design minimizes over-production today, while accommodating future needs. The design considers both product obsolescence and new product introductions – so the firm can quickly respond to both needs. Lean business tools can be adopted in virtually any industry and line up nicely with Six Sigma. Six Sigma’s qualitative and quantitative techniques can support the Lean Business Model by driving process improvement and reducing timelines.

Improved costs

Lean companies train each employee to identify wasted time and effort. They also emphasize working together as needed to eliminate the discovered waste. The ability to recognize and eliminate waste is essential to improving business costs. But, a boost in operational excellence that results from Lean Six Sigma activity provides many complementary cost benefits as well. For example, improved timelines reduce inventory and person-hour costs.

Excellence, lower costs, and product leadership

A focus on operational excellence sets the firm on a path to success. By attending to overall performance, measured in MTTRCCD, the firm can naturally achieve what seems impossible – innovative, cutting-edge products at cost leadership prices.

Next steps

Because Lean tools and principles can be applied to so many different industries worldwide, professionals in many different environments and different stages in their careers should take advantage of learning these Lean Methods. Thousands of global organizations adopt Six Sigma metrics and methods. This practice delivers dramatic performance improvement and cost savings. Advanced programs such as a Lean Six Sigma certification program will provide support so the firm can demonstrate its competitiveness in the current manufacturing and business marketplace.

Purdue University offers comprehensive, online Lean Six Sigma (LSS) certificate programs spanning a range of levels for differing levels of experience. The following online Purdue University courses could be a great start:

Alternatively, the Business Excellence Institute provides an educational foundation in building competencies as a Certified Excellence Assessor (CEA). CEAs us using an excellence assessment framework to assess an organization within its industry objectively. The assessment outcome provides senior executives and senior management with actionable deliverables. Those outcomes could trigger more profitable or effective financial results, innovation, continuous improvement, organizational development, and the crafting of new, more refined strategies. Additionally, BEI provides certification as a Chartered Business Excellence Professional (CBEP).

If the goal is just to become immersed in the topic, without a significant financial commitment, the following courses may prove satisfactory:

- Key Success Factors to Drive Operational Excellence;

- Continuous Improvement Tools;

- Manufacturing Operational Excellence Foundation: Lean Manufacturing; and

- Quality Management Systems for Operational Excellence.

Give one a try! As a lifelong learner, the goal is to continue to acquire new learning.