An overview of value stream mapping

There is a reason why we still go to the whiteboard for many activities in business. By sketching out visual models to represent processes, flows, states, or other modular concepts, we can better grasp the interactions between components and see the importance of different elements. Value Stream Mapping is a visual modeling method we can use in business, particularly software development, that has its roots in lean manufacturing.

Value Stream graph

Value Stream graph

“A Value Stream Map (VSM) is a process flow chart that shows each step in the production of a good or material, as well as the resources used in each step, and the relationships between the resources. Value stream mapping is a very significant component of any Lean initiative, providing a framework that highlights waste and the negative effect it has on overall process performance and flow.”

– King and King (2017, p. xiii)

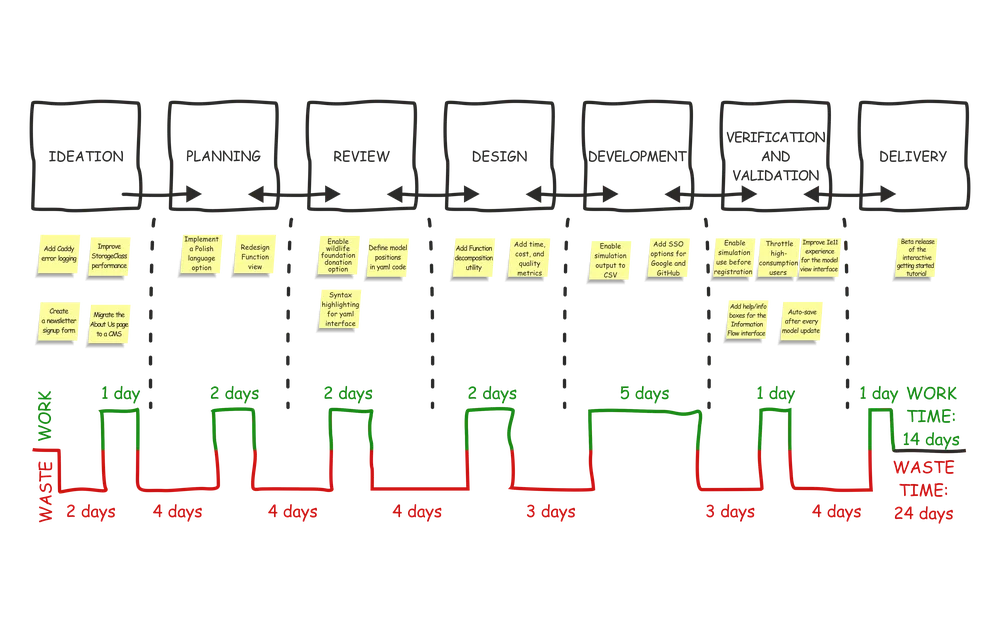

Value Stream Mapping is a valuable visual tool for understanding the flow of ideas, code, artifacts, and assets. The resulting map provides a blueprint: insight into the value-added activities and the activities which are non-value-added, from ideation through to successful customer outcomes. The Value Stream Map includes all actions required to deliver a product, service, or feature.

Lean principles from manufacturing and Value Stream Mapping

Lean principles derived from manufacturing underpin the activities involved in Value Stream Management - concepts of value and waste are central to the analysis. Undelivered features, products, and services provide absolutely no value or benefit to our end customers. Value streams should reflect this and seek to minimize work-in-progress.

The basic principles of timeline sequencing include (King and King, 2017, p. 122):

- There is usually a logical sequence in which completed improvements set the stage for other improvements, where having some of the improvements in place makes the further improvements easier to implement or provides a higher likelihood of their success. This logical sequence should have the highest priority in determining the overall order of implementation.

- High benefit opportunities should be done as soon as is practical, but not at the expense of following a logical path.

- Things should be implemented in a sequence that eliminates re-work. For example, product wheels should be designed after cells are in place because the cellular design process will likely change the allocation of products to specific pieces of equipment and thus the wheel designs.

- Implementations should be phased out as needed to avoid overloading the implementers.

The objectives of Value Stream Mapping

The objectives of Value Stream Mapping are NOT to:

- Build complex models that are difficult to grasp, or

- Use a language of icons and diagrams that require special knowledge to interpret.

The objectives are to:

- Simplify and clarify the value-added activities in a Value Stream,

- Define consistent, easily interpretable maps of processes,

- Use Value Metrics to quantify the Value Stream (e.g., time taken to complete an activity),

- Focus on value-added activities and eliminate waste.

Value Stream Management

Value Stream Management seeks efficiency and efficacy in product/service definition, product/service realization, and customer success (selling, delivering, supporting, etc.). The culmination of each of these objectives requires cross-disciplinary excellence in product, operations, and customer success.

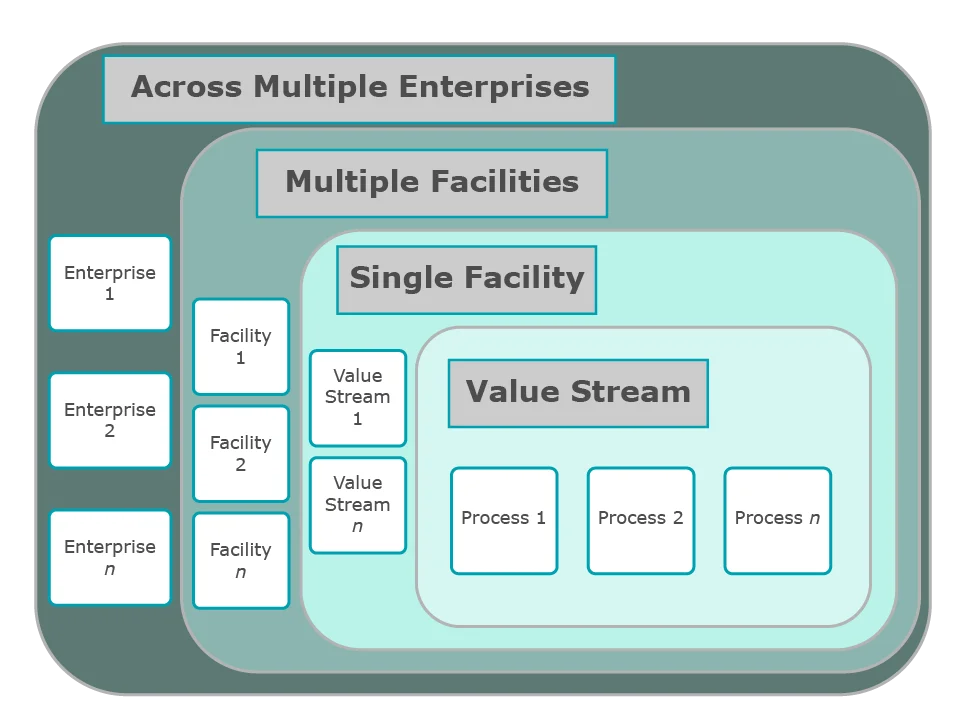

Multiple levels of mapping enable various levels of insights for Value Stream Mapping. At a minor level, one might detail an individual process. At major levels, the flows can cross organizational boundaries (e.g., customers, service providers). While we can look at our Value Stream Maps and identify the location for value-added improvements, strong Value Stream Management focuses on improving the whole, not just optimizing pieces of the process.

Value stream levels

Value stream levels

Steps in drawing a Value Stream Map

Before we start mapping

Getting started with Value Stream Mapping/modeling requires three initial steps, derived from more generalized Process Mapping (Hunt, 1996, p. 194).

- Purpose (Objective) - Detail why Value Stream Mapping is needed (e.g., to shorten lead time)

- Viewpoint (Bias) - Define the analysis perspective, how the model will be used, and how the model should communicate information

- Context (Subject) - Establish the subject of the model and the scope/boundaries

Why are we doing this? Who is the intended audience of the Value Stream Map? What are the boundaries of the map?

Drawing out our current Value Stream Map

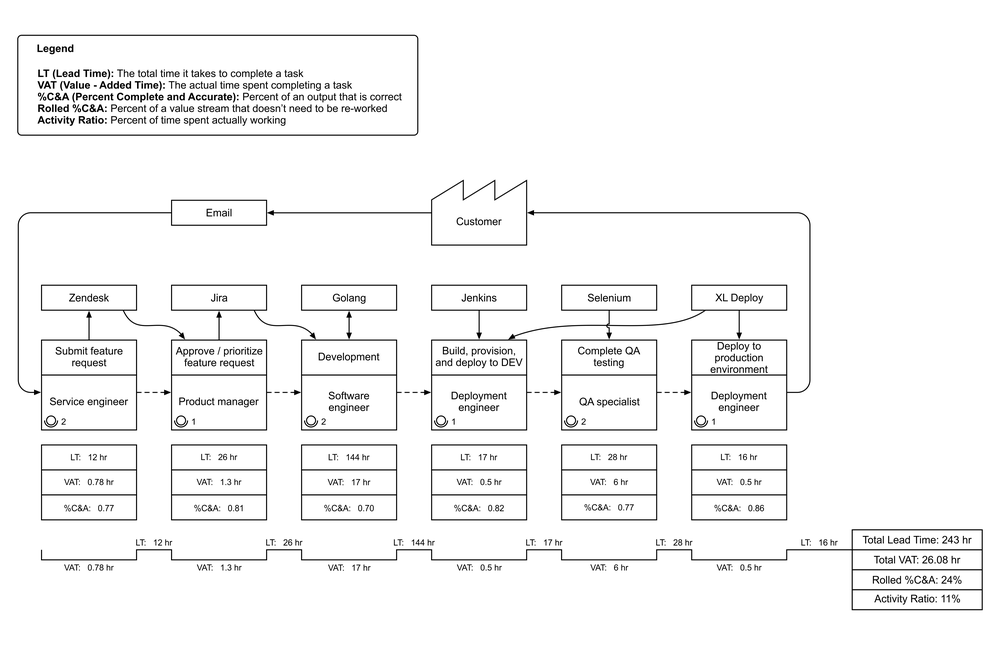

Once the Value Stream Mapping context is defined, the flows are defined. These may include product, information, knowledge, code, artifact, idea, and asset flows - with links between the flows. The Value Stream spans functional boundaries. Using repeatable icons and lines for flows and links will ensure documentation remains consistent across the organization. Adding a key to maps will help readers unfamiliar with the format.

Detailed Value Stream

Detailed Value Stream

Drawing a future Value Stream Map

Initially, the team will map out the current state. Subsequently, an organizational team will typically map out future states, implement them, and then repeat the process iteratively. We know where we are now, so we know where we can improve and what targets we want to hit: our future state.

Next steps

Just like physical product inventory, features, bug reports, documentation, and specifications can all “spoil” as a product evolves. These spoilages are costly and provide no value to end customers. Effective Value Streams minimize these, sometimes at the expense of labor utilization. Like manufacturing, it may be most profitable and beneficial for employees to sit idle instead of overproducing and disrupting the value flow!

As Value Stream Mapping becomes common in organizations, it can serve as a common language to talk about business and development processes. Organizations develop a clear understanding of how the business works and detail possible future states.

Metrics will provide a baseline and quantify the impact of improvements. When kept simple and easy to understand, Value Stream Mapping can be a valuable tool for organizations to know where they are and where they need to go.

Several inexpensive seminars and courses could help situate the team to perform better Value Stream Mapping:

- Value Stream Mapping Masterclass: Become a VSM Specialist,

- Six Sigma Advanced Improve and Control Phases,

- Value Stream Mapping Primer: Current State to Future State.

References:

Hunt, V. D. (1996). Process mapping: how to reengineer your business processes. John Wiley & Sons.

King, P. L., & King, J. S. (2017). Value stream mapping for the process industries: Creating a roadmap for lean transformation. CRC Press.

Rother, M., & Shook, J. (2003). Learning to see: value stream mapping to add value and eliminate muda. Lean Enterprise Institute.